CorsaGSI_DK

Member

Registered: 10th Jun 02

Location: Copenhagen, Denmark

User status: Offline

|

Encouraged by Dave A I have made this thread so that people (if they like) can follow my complete rebuild. The engine is an x16xe.

I have NEVER done anything crazy like this before! I have a master degree as chemical engineer and 3,5 years as a Ph.D in biotechnology! Two years ago I didn't even dare to change my brakepads!

I'm so fortunate to have a good friend who is a really good mechanic (and teachter) and he has built 4 Saxo Cup race cars and lots of other cars.

We started to remove the engine Friday evening and after 4 hours we decided to stop and carry on next day. At this point I was already getting a bit nervous! So many wires and hoses  But everything was marked when removed. But everything was marked when removed.

Saturday we carried on and after another 4 hours the engine was standing on a pallet! We found out that we had spent 2-3 hours to much in trying to remove some of the wiring loom which was not necessary. Not easy to know when it is first time your trying. Some picturs of the engine on the pallet.

All the plugs on the wiring loom in the engine was packed in small bags to avoid any water in it.

Sunday I started to dismantle the engine. Again a lot of hoses and wires :-( It was stripped down to only metal and the gearbox was removed.

Original fitted with a Sachs clutch.

Monday evening the rest of the engine was dismantled.

Here is the stripped engine block. Every little bolt and nut was packed in small plastic bags and a note was written on the bag (for starter, for generator, for oilpump etc.)

The engine block was like new!  After 125.000 km the cylinders did not have any marks at all! After 125.000 km the cylinders did not have any marks at all!

The crank also seemed like new. Only a very faint mark was noticeable at bearing number 2. I was told not to worry about this because new bearings will be used.

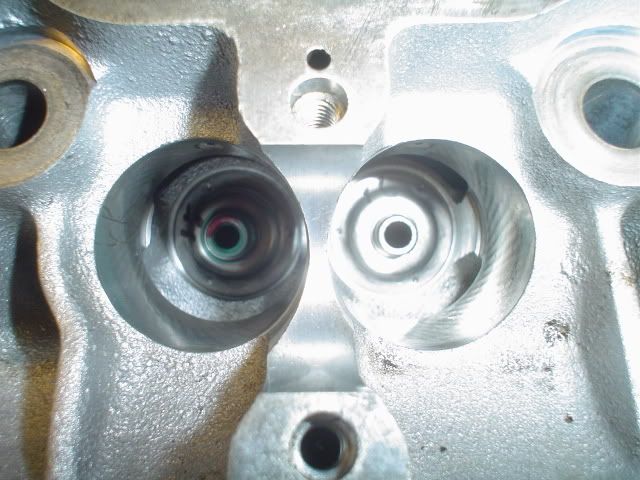

A picture of the inlet port from the original head. Also looked like new:

A new (used) head will be fitted. It has been ported. Here's a picture of the ported port:

The head is at the moment completely separated.

I bought it with upgraded valve guides, springs and titanium valve caps/retainers

Tuesday I delivered the engine block for a re-bore to fit the new forged pistons. Today the company called me and asked for the engine code (x16xe) because they had ruined it when they did the re-bore (the cylinders were now oval!). They told me it wouldn't be my problem and they would find me a new (old) one.

3 hours later they rang me back and told me they had found a new engine block and they would get it tomorrow. They would do the re-bore free of charge because of this mistake. So despite of this "little accident" I hope I will get my engine block back on Friday. Then the FUN will begin...when all the new stuff will be put in :-)

All the new parts can be seen in an old thread: http://www.corsasport.co.uk/board/viewthread.php?tid=317916

Hopefully I can add some Eagle steel rods very soon (bought from Mr. Broster).

If people are interested I will try to keep this thread updated.

Cheers,

[Edited on 08-11-2006 by CorsaGSI_DK]

|

Robin

Premium Member

Registered: 7th Jan 04

Registered: 7th Jan 04

Location: Northants Drives: Clio 182 Cup

User status: Offline

|

yes, keep us updated, it will be intresting

|

deano87

Member

Registered: 21st Oct 06

Location: Bedfordshire Drives: Ford Fiesta

User status: Offline

|

I'm interested - not because I'll ever be able to do anything like that but because I am just amazed with it.

|

VegasPhil

Premium Member

Registered: 16th Jan 05

Registered: 16th Jan 05

Location: Fareham, Hants Drives: Octavia VRS

User status: Offline

|

'Mazin

Corsa 2.0 16v Vegas - Sold

|

Marc

Member

Registered: 11th Aug 02

Location: York

User status: Offline

|

Whats the ultimate aim then? Crazy 1.6 or just a mild state of tune?

|

CorsaGSI_DK

Member

Registered: 10th Jun 02

Location: Copenhagen, Denmark

User status: Offline

|

I don't build the engine because I have a specific aim to reach. I do this becuase I can (with some help) and because I think it is fascinating.

Engine block (crank, pistons, rods) should be good for 9.000 rpm. Head should be good for ++9.000 rpm. Fast road cams, vernier pulleys and metal cambelt rollers will also be fitted.

TB's are out of questions because of the Danish MOT's. So I have to stick with my Mantzel (copy) box.

The effect of the engine? I don't know. We will see when it's going to be remapped on a rolling road. I looking for 8.000 rpm and around 150 bhp.

|

Dave A

USER UNDER INVESTIGATION - DO NOT TRADE

Registered: 10th Dec 03

Location: County Durham

User status: Offline

|

|

CorsaGSI_DK

Member

Registered: 10th Jun 02

Location: Copenhagen, Denmark

User status: Offline

|

Time for an update!

Last week the company which was going to do the re-bore called me and told med that they had a small "accident" with my engine block  Here's a few pictures of the ruined block: Here's a few pictures of the ruined block:

Not the best start! The company found me a new (old) engine block and did the re-bore. This time the managed to "find" the right holes

Block was done to fit new pistons, 79,50 mm. This is the final result:

I have also managed to assemble the head after it was skimmed. The head was dismantled completely when this was done. All valves, springs, valve-caps etc. was separately numbered and placed in small plastic bags. This is exhaust valve, spring etc. for valve number 9.

New high-performance valve-stem seals were fitted.

The first few valves take a long time to fit. After that you learn how to do it. This is the tool used to fit the valve springs:

All 8 inled valves fitted with titanium valve-caps:

The fly-wheel was balanced and 1,6 Kg of metal was removed! Looking forward to see if I can feel a difference. 1,6 Kg should be noticeable when it is mainly taken from the periphery of the fly-wheel:

I also received some steel rods - bought from Mr. Broster.

Unfortunately I could measure a slightly to large tolerance/clearance between the piston-pin and the pin-hole in the rods. Most companies recommend 10-15 micro-meter of clearance. Had a discussion with Mr. Boster and he accepted to return the money if I could not use the steel rods. Nice guy!

Friday I drove 200 km to visit a company - which know a lot about engines, pistons and rods - to get their oppinion about the clearance. They told me the clearance was acceptable, which was very nice to hear.

Also managed to paint my inlet-manifold. Very pleased with the result...although not 100% perfect:

Tuesday I will test assemble the crank and rods - with the new bearings - using some plastigage to verify the clearance of the bearings is within the acceptable range.

Then, hopefully, the engine can be assembled on Friday/Saturday and will be placed right back - in the empty hole under the bonnet - where it belongs:

|

Robin

Premium Member

Registered: 7th Jan 04

Registered: 7th Jan 04

Location: Northants Drives: Clio 182 Cup

User status: Offline

|

what happened to the block? I can't work it out.

|

CorsaGSI_DK

Member

Registered: 10th Jun 02

Location: Copenhagen, Denmark

User status: Offline

|

They missed the center of the cylinder and was app. 1,5 mm off the center. Hence the large mark in the top of the cylinder

|

Robin

Premium Member

Registered: 7th Jan 04

Registered: 7th Jan 04

Location: Northants Drives: Clio 182 Cup

User status: Offline

|

Ah, I can see it now. Nice of them to source a new block for you though.

|

Marc

Member

Registered: 11th Aug 02

Location: York

User status: Offline

|

quote:

Originally posted by CorsaGSI_DK

I don't build the engine because I have a specific aim to reach. I do this becuase I can (with some help) and because I think it is fascinating.

Engine block (crank, pistons, rods) should be good for 9.000 rpm. Head should be good for ++9.000 rpm. Fast road cams, vernier pulleys and metal cambelt rollers will also be fitted.

TB's are out of questions because of the Danish MOT's. So I have to stick with my Mantzel (copy) box.

The effect of the engine? I don't know. We will see when it's going to be remapped on a rolling road. I looking for 8.000 rpm and around 150 bhp.

Judging by that and what you've posted since a mildy tuned engine then.

|

broster

Premium Member

Registered: 6th Dec 02

Registered: 6th Dec 02

Location: Drives: E39

User status: Offline

|

glad to see it going back together matey!

|